Mechanical plant room is the space in a building that is solely dedicated to the equipment linked to the mechanical services and the relevant associated electrical equipment. The mechanical rooms are provided to provide a clean and clear human occupancy in a building. The mechanical plant room basically houses the following equipment:

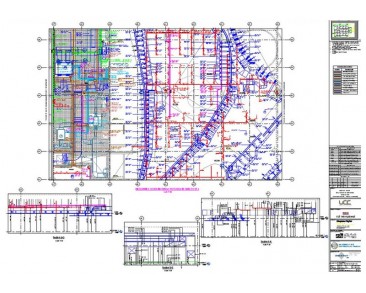

For a stadium project, we coordinated the equipment in the mechanical plant room. As stated above, all the mechanical services are housed by mechanical plant room hence, our job was to create a coordination between all the mechanical services involved in the project.

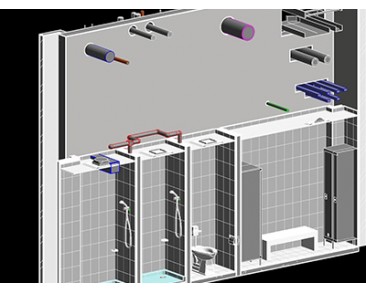

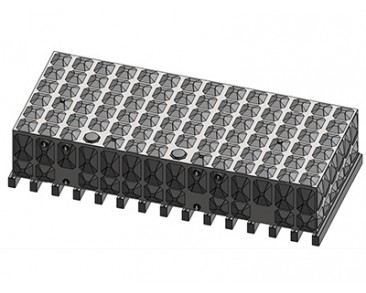

We initiated by thoroughly studying the basic information we had about the project, as collected from the client. After going through all the information, we created families for each of the equipment being used in the project. By creating families, we could handle the information in a more precise way and could use them in the models more accurately.

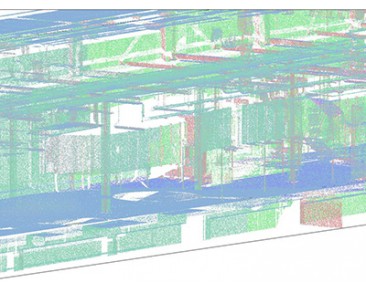

After creation of the relevant families, 3D models for the plant rooms were created. The 3D models thus created were then coordinated to detect any clashes between different equipment. The minimal clashes that were detected were discussed with the concerned stakeholders and then finally resolved.

The final coordinated models were created for the same. The coordination between different equipment before the start of the project reduced the chances of rework to nil.